The Problem

The Problem

This Land Rover client presented us with a 2015 Evoque with a Check Engine Light (CEL) on, and noise from the engine.

On inspection, our Land Rover technician verified that the CEL on, and carried out a visual assessment. Then using the diagnostic computer we checked and scanned for codes. We found the following fault codes, P052A – Cold start camshaft timing over advanced bank 1, P0011 – Intake camshaft position timing over advanced bank 1, P0341 – Camshaft position sensor A circuit/range performance bank 1.

Fault codes are only a starting point, we never use them for component replacement without additional testing and inspection. We also use the codes in conjunction with factory service bulletins, and a large database of common pattern failures…35 years of experience is pretty helpful too. 😉

When these faults occur, the first step is always check the solenoid valve value and resistance, then to measure the VVT adjustment angle. Finding these out of spec, we always start with a quote to replace the VVT, and camshaft sensor while apart, followed by an inspection when the VVT solenoid device is carried out.

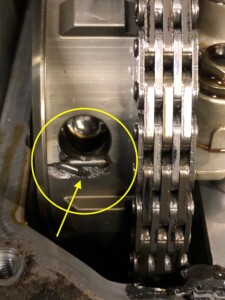

Following the test plan, our technician then removed the engine cover and found an excessive oil leak, and that the plastic valve cover was cracked. This is a very significant finding, much indicative of an internal engine failure. As it was very possible something has broken in the engine timing system, he next removed the camshaft cover and external engine components and found a failure of the camshaft retaining pin.

How It Works

Like many newer cars, Land Rover uses a system called “Variable Valve Timing” (VVT) in which the engine valve timing is controlled dynamically via engine oil pressure and electric solenoid valves. The aim is to improve volumetric efficiency, decrease NOx emissions, and decrease pumping losses. Today, there are two major types of variable valve timing: cam phasing and cam changing. With cam changing, the ECU selects a different cam profile based on engine load and speed, whereas, with cam phasing, an actuator rotates the camshaft, changing the phase angle.

There are dozens of ways to go about varying valve timing, lift, and duration control, Land Rover uses the solenoid valve method, controlled by the engine computer. These valves allow the oil to flow into a VVT gear on the end of each camshaft, allowing the engine timing to be varied to provide better performance and fuel economy. The system, provided that the engine oil is kept clean and full, is generally very trouble-free.

Because the cam sprocket needs to move for the VVT system to work, it must have a mechanical stop, so it does not over-rotate, and for retention. It is this stop, pin, or keeper that fails, and creates the problem that we found. So with that in mind, the most common cause of the Land Rover VVT or VCT sprocket failure is the failure of the retaining pin on the intake camshaft, what Land Rover calls the “VCT Stopper”. Often caused by a stuck or defective camshaft control solenoid, that allows the VVT sprocket to “bounce” with low or inconstant oil pressure.

Land Rover’s exact phrase for the problem is “This may be caused by the ‘stopper’ in the intake camshaft Variable Cam Timing (VCT) actuator becoming detached, leading to the VCT actuator not functioning.” Which is a polite way of saying something really bad just happened.

Usually, the Land Rover VVT or VCT sprocket failure comes on as the vehicle gets on in miles, our experience, and industry reports seem to typically indicate at 60,000 to 80,000 miles. Often caused by a stuck or defective camshaft control solenoid, that allows the VVT sprocket to “bounce” with low or inconstant oil pressure. This may also be caused to be some weakness in design or manufacturing, resistance from advancing and retarding camshaft position becomes too much, causing the weakest part, the pin to break.

The only true and permanent repair in the event of a damaged VVT sprocket is to replace the intake VCT sprocket, timing chain, and all guides with the newer, and an updated design, while properly cleaning and servicing the cylinder head. Any “repairs” are usually very short-lasting and risk having failed parts fall into your engine, or worse, a catastrophic engine failure, resulting in very expensive engine damage and quite possibly ruining your engine. It’s just not worth the risk, do it right the first time, and it’s good to go.

Value

At Atlantic Motorcar, we’re all about providing our customers not only Great Service but also Value. We understand that “An ounce of prevention is worth a pound of cure.” (my mom would be proud I remembered that.), in other words, preventing, or catching problems like these brake lines early, can save you more than just money.

Finally

Questions, or if we can be of help in any way with service on your Audi, BMW, Mercedes, Mini Cooper or other European (and now Japanese) import, please contact us. Our team of Service Specialists is here to help, for even the newest autos! (207) 882-9969.

Knowing, not just “doing”, that’s the Atlantic Motorcar Center way.

Thanks!

Warmly,

The Atlantic Motorcar Center Service Team

Symptoms of Fuse Failure

Symptoms of Fuse Failure What to Do Next

What to Do Next Many owners of late-model Mercedes-Benz cars equipped with 3.0 and 3.5l V6 engines (M272 or M273), as well as some of the later V8s, have or will likely soon experience a near-universal Mercedes Benz intake manifold problem. Generally, we find problems in performance, which include poor idle, loss of power, and a Check Engine Light.

Many owners of late-model Mercedes-Benz cars equipped with 3.0 and 3.5l V6 engines (M272 or M273), as well as some of the later V8s, have or will likely soon experience a near-universal Mercedes Benz intake manifold problem. Generally, we find problems in performance, which include poor idle, loss of power, and a Check Engine Light. th intake runner manifold can switch between two sets of intake runners with a flap built into the manifold. This way, you can have one set of intake runners optimized for when the car is idling, and picking up low RPM speed. Then if you get on the throttle and request power for sportier or more demanding driving, the flap switches over to the second set of intake runners that is optimized for the higher rpm range. Many of these intakes also have specifically shaped flaps that cause a vortex, adding even more efficiency.

th intake runner manifold can switch between two sets of intake runners with a flap built into the manifold. This way, you can have one set of intake runners optimized for when the car is idling, and picking up low RPM speed. Then if you get on the throttle and request power for sportier or more demanding driving, the flap switches over to the second set of intake runners that is optimized for the higher rpm range. Many of these intakes also have specifically shaped flaps that cause a vortex, adding even more efficiency. Problem

Problem

We’ve all heard it. That smell that could be who knows what coming from the vents of your car or under the seat or in the upholstery itself. You’ve tried cleaning and scrubbing, baking soda, everything you can think of, all of the tips in our post about cleaning your car’s interior. When all else fails, the next step is an ozone treatment. You may have heard of it. Ozone machines are the area of professional detailers. We’ll break it down for you here.

We’ve all heard it. That smell that could be who knows what coming from the vents of your car or under the seat or in the upholstery itself. You’ve tried cleaning and scrubbing, baking soda, everything you can think of, all of the tips in our post about cleaning your car’s interior. When all else fails, the next step is an ozone treatment. You may have heard of it. Ozone machines are the area of professional detailers. We’ll break it down for you here.

What Does Cupping Look Like?

What Does Cupping Look Like? Is It Possible To Repair Tire Cupping?

Is It Possible To Repair Tire Cupping? What Happens

What Happens n the photo, you’ll note shards of serpentine belt material that are inside of the engine. How does serpentine belt material end up inside an engine? It’s due to the design of the harmonic balancer/crank pulley assembly on these engines and the position of the serpentine belt relative to the engine block. The oil filter housing leak, when severe enough, can create a trail of oil all the way down the front of the timing cover, eventually coating the serpentine belt and crankshaft pulley. Once the oil is on the serpentine belt and the crank pulley portion of the harmonic balancer, it’s almost inevitable that the serpentine belt will begin to degrade and come off the tensioner pulley. Since the harmonic balancer is in front of the crank pulley, the serpentine belt has nowhere to go but back towards the timing cover if it slips off. Once it slips off the crank pulley, it shreds the belt and forces the pieces through the front crank seal.

n the photo, you’ll note shards of serpentine belt material that are inside of the engine. How does serpentine belt material end up inside an engine? It’s due to the design of the harmonic balancer/crank pulley assembly on these engines and the position of the serpentine belt relative to the engine block. The oil filter housing leak, when severe enough, can create a trail of oil all the way down the front of the timing cover, eventually coating the serpentine belt and crankshaft pulley. Once the oil is on the serpentine belt and the crank pulley portion of the harmonic balancer, it’s almost inevitable that the serpentine belt will begin to degrade and come off the tensioner pulley. Since the harmonic balancer is in front of the crank pulley, the serpentine belt has nowhere to go but back towards the timing cover if it slips off. Once it slips off the crank pulley, it shreds the belt and forces the pieces through the front crank seal.

The Problem

The Problem

Drains aren’t just for bathtubs, or the kitchen sink, they also exist in your car to drain away from the effects of rain, ice, and snow. Yet, they’re one of the most neglected of service items. Often considered only when it’s too late.

Drains aren’t just for bathtubs, or the kitchen sink, they also exist in your car to drain away from the effects of rain, ice, and snow. Yet, they’re one of the most neglected of service items. Often considered only when it’s too late.