Be it an Audi, BMW, Mercedes, Saab, or Volvo, one question we get asked almost daily is about grinding brakes, especially so first thing in the morning.

Q – We often get a question about why a car makes a grinding noise when applying the brakes the first thing in the morning, or after it has been sitting a few days. Sometimes this noise can be quite loud.

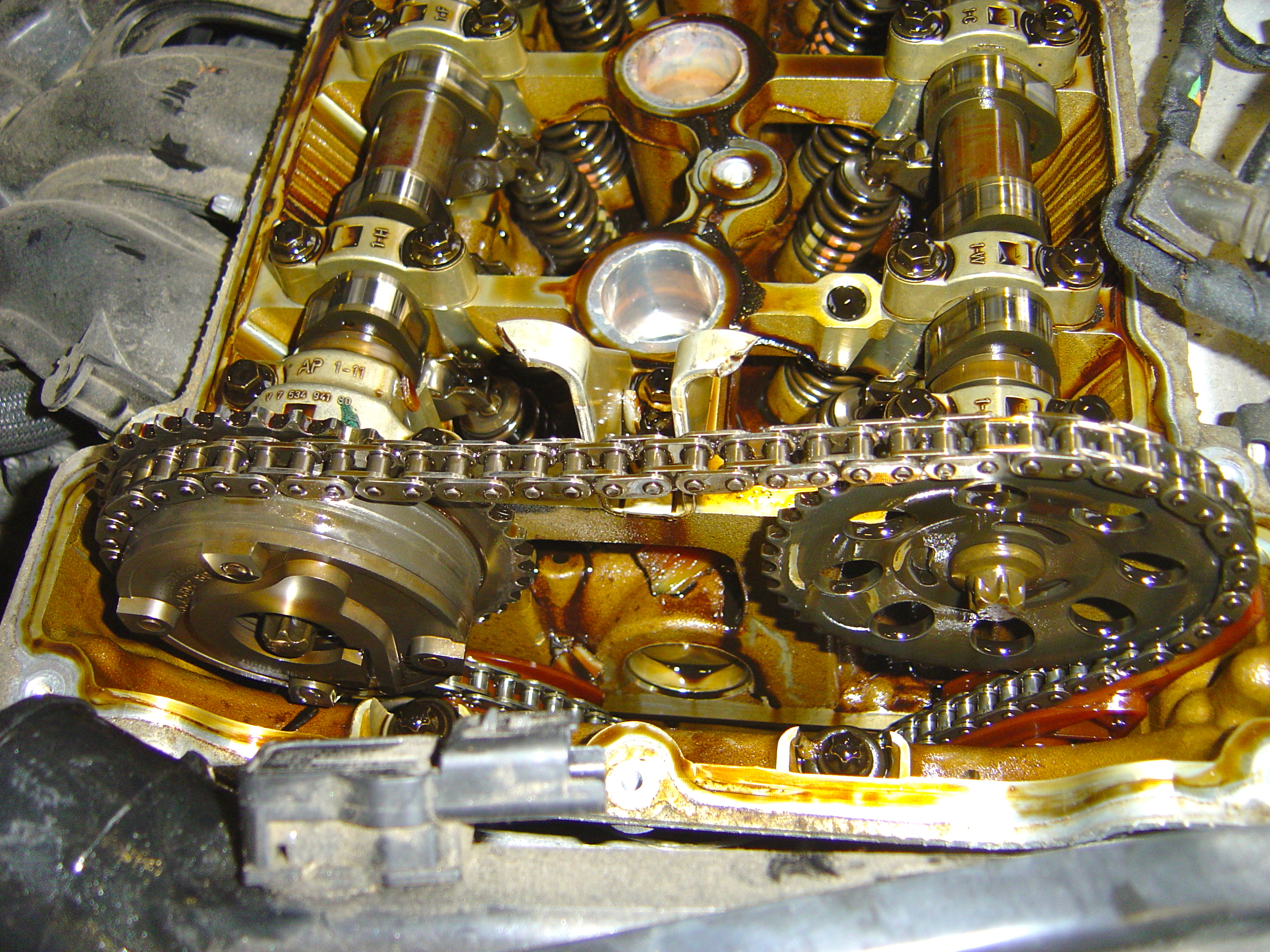

A – This is usually cause by rust on the brake rotors, and brought about by the semi-metallic brake pads – brake pads, especially those used by European manufacturers like Audi, BMW, Mercedes, Saab and Volvo, have metal particles embedded into the pad, this aids in stopping and making the brake pad last longer. When you car is sitting, the metal particles in the brake pads rust onto the metal brake rotors, creating the noise you hear when you drive off. Sometimes, if the car has been sitting for a few days, you might even hear a “snap” or feel a binding as the brake pads and rotors release.

If it’s been awhile since you last brake service, then you may want to use us do a quick safety check on your brake system, just to make certain. We check your car’s brakes each and every time it is here for service, your safety is always our #1 priority.

Questions, just call us at 882-9969.

We cover the Maine coast, from Falmouth to Camden.